Fabrication

Our capabilities

Fabrication:

Our expertise in fabrication covers centrifuges, coatings, design and build, engineering services, fiberglass products, filters, fluid handling equipment.

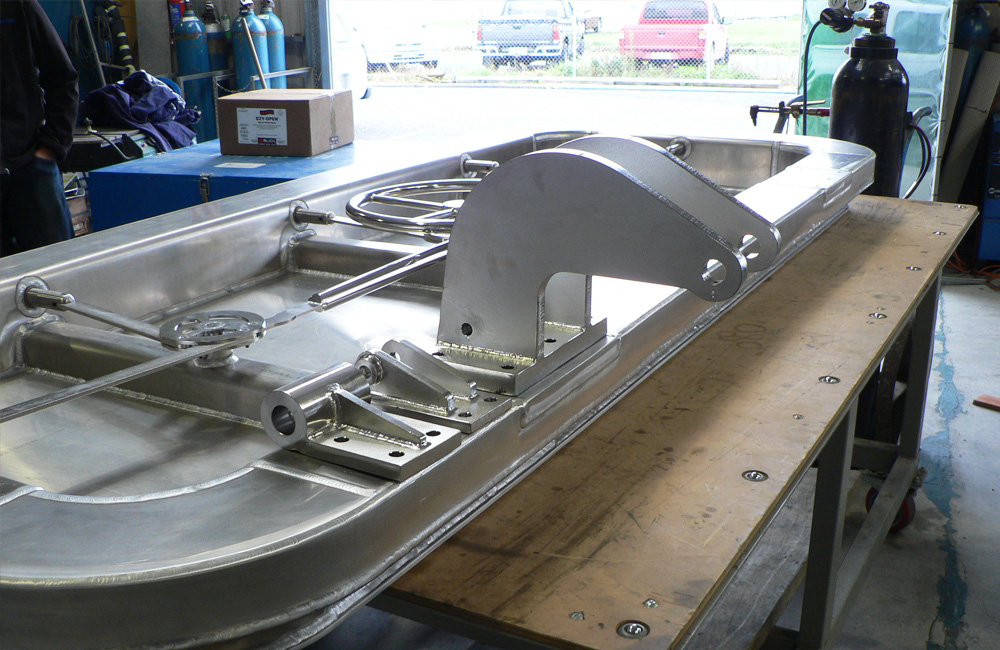

Design and manufacture of centrifuges for the oil and gas exploration industry.

Full blast and paint capacity as part of the fabrication process.

Full design build capacity of most project types and industries, tailored to your needs.

Mechanical fitting, coded welding, noise control equipment, transport engineering, pump overhaul, leak sealing, compressor services, press braking and guillotining.

Centrifugal and axial fans for corrosive and moist gases, offering low maintenance, high corrosion resistance and low noise for long service life, as well as high efficiency CLUB fans, self cleaning CMHP fans, high pressure CH & CHP fans, axial fans and sound attenuation.

Ducts, hoods, stacks, pipes, sewers, tanks, sumps, manholes, liners, pump stations, flumes, tank covers and marine exhaust tubes.

Vertical or horizontal particle filters and vertical coalescing filters, gas stream or liquid stream.

One of our members is the premier supplier of oil exploration fluid handling equipment throughout the Asia-Pacific region.

Mild steel and alloy vessels, tanks, pipework, heavy plate fabrication and sheetmetal work. To date our members have completed materials handling equipment fabrications up to 800tonnes, 100m long and 35m tall.

Fin/fan coolers, shell and tube, u-tube, gas/gas, heat transfer coils, repair and tube replacement.

Heavy plate-rolling and fabrication of large diameter sections to ASME VIII, AS1210, BS 5500 and API 650 codes. Especially for the oil and gas and petrochemical industries, for products such as LPG bullets, surge drums, boilers, heat-exchangers and oil storage tanks. Also large stainless steel clad and 2205 duplex stainless steel pressure vessels.

Design and fabrication of Intermediate Bulk Containers (IBCs) to UN Standard 31A.

Machine tools include horizontal borers, vertical borers, plano mill, planer, CNC and centre lathes, milling machines, sharpers, radial drills and surface grinding equipment.

Machining services are available for flange facing, ring joint grooving, line boring, leak sealing and high speed heavy cutting, as well as hot work toolsteel.

The consortium also provides competitive services in the following areas: in-situ (on site) line boring, milling and shaft turning, boiler man way door grinding, band saw wheel re-sleeving, in-situ (on site) flange facing, pipe cutting, weld preparation.

We are experienced in machining exotic materials such as titanium, SAF2205, Duplexs, aluminiums, plastics as well as the standard steel ranges; Tool and cutter sharpening such as rotobroaches and machine assisted drill-sharpening service up to 80mm; Keyway broaching both metric and imperial, Extensive stocks of boilerplate for the manufacture of flanges for the petrochemical and boiler industries; Specific machining skills for the oil and gas industry including offshore platform work, and general large capacity machining.

Housings, brakes, studs, tanks, bolts, componentry, compressors and centrifuges.

Large a small materials handling equipment, including a coal ship loader, bucket wheel coal reclaimer, various conveyors and sea anchors for off-shore platforms.

Design and manufacturing replacement screens for linear motion shakers, all brands.

Design and fabrication of linear motion shakers for the oil and gas exploration industry across Australasia, Asia-Pacific and the Americas, utilising carbon steel, stainless steel, duplex, clad, plate, alloys, aluminium, chrome moly, titanium, exotic materials, fibreglass, plastics and hot work toolsteel.

Airport fueling system fabrication, gantry cranes, stacks and ducting.

Hot work steel component manufacture of containers, stems, butt shears, bolsters, tooling, liners, fixed pads, liner changeout service, and shift and pull back cylinders manufacture.

Complete modularisation capacity and experience for multiple project types and industries, including skid mounted process equipment. Servicing the Maui A and Maui B offshore oil and gas platforms, together with the FPSO Whakaaropai, has resulted in a solid track record of fully built prefabricated and pre-commissioned module construction. Typically this modular approach has been used effectively for “brown field” enhancement of existing offshore facilities with great success.

Design and construction of mud tank systems for oil drilling and exploration industry. Systems designed and constructed for high quality mud and solids control in diverse environments.

High pressure piping built to ASME, API, BS, AS, and ISO standards using carbon steel, chrome moly, stainless steel, duplex, inconels, and titanium.

Computer assisted (CNC) plate stripping machinery, with have bed sizes up to 3.6m wide by 12m long and capable of cut thicknesses up to 75mm for carbon steel.

Portable water and wastewater systems fabrication

Process absorbers, chemical reactors, gas storage bullets, product stills, digester vessels, refining columns, gas regeneration, vacuum columns, flash vessels, extraction vessels, molecular sieve absorber vessels, naphtha column, debutaniser column, hot oil heater, stripper vessels, bio-filter reactors, dry scrubbing vessels, torbed reactors, methanol refining columns, separators. Built to ASME, API, BS, AS, and ISO standards. Manufactured pressure vessels up to 65m long and 8m in diameter, and stainless steel vessels for the dairy industry, designed to BS5500 and MAF approved.

Petrochemical processing, produced wastewater disposal, oil and gas, naphtha processing skids.

Sapstain sprayers

High volume sapstain sprayers for the timber industry.

Plate rolling capacity up to 75mm in a variety of materials to specified diameters. Heat treatment has provided the ability to roll plate over 100mm thick.

Sports stadiums, industrial buildings, museums, platforms, walkways, warehouses, factories, car parks, oil and gas processing plants, power stations, pipe bridges, timber processing plants.

Stainless steel and carbon steel storage tanks, hoppers, process tanks, to API Tank Standards.

Waterbath heater fabrication.

Welding qualifications include: ASME IX, BS EN 288, ASA 1210 AND NZ4711.

Oil Industry vacuum degassers based on field proven technology that has been the industry standard for 30 years. Designed and built to international oil industry standards.

Super yacht fabrication and black boat capability.