Engineering Design

Our capabilities

Engineering Design:

Our design capabilities cover feasibility studies, front-end engineering design (FEED), general design, heat exchanger design, mechanical and piping design.

Our front-end engineering group considers ideas and associated risks and then rigorously tests feasibility of implementation within strategic constraints. This is not limited to just technical challenges but combines financial evaluations with socio-economic considerations to deliver optimised recommendations for maximum value.

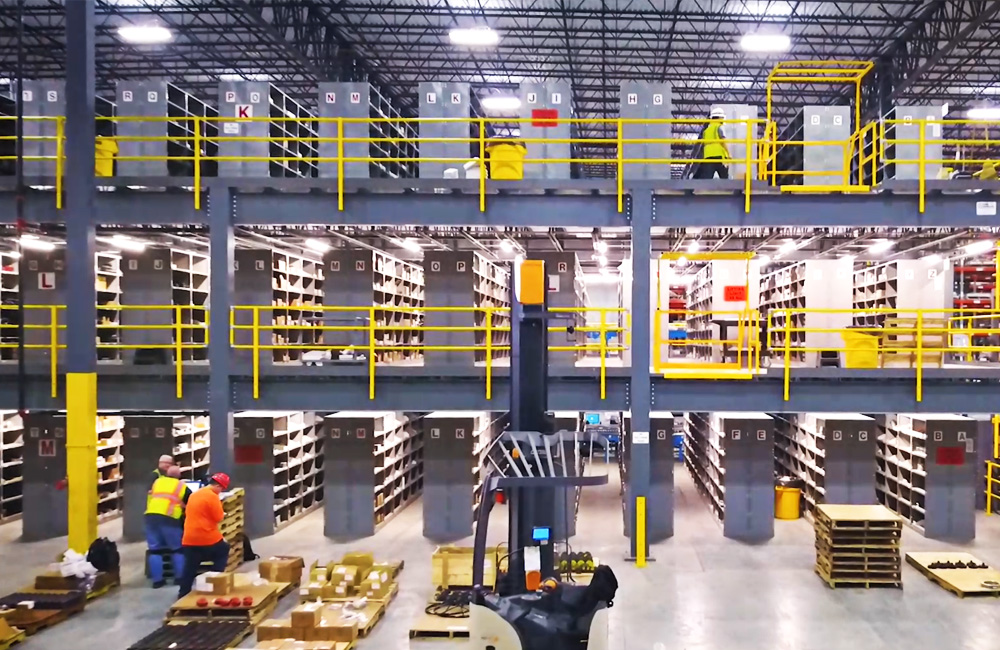

Pipe supports, pipe racks, equipment support structures and skids, conveyor and material handling systems, buildings, lifting equipment and production modules. The consortium can also deliver detailed design for modifications to existing platform building and structures.

Thermal and mechanical design of heat transfer equipment including shell and tube heat exchangers, fin-fan coolers, double pipe exchangers, direct fired heaters. Also indirect heaters to API 12K, ASME, NFPA54 or AG501, with integral controls, burner or fuel oil train.

- Advanced process control

- Instrumentation and electrical contracting

- Instrumentation and electrical installation

- Instrumentation and electrical maintenance

- Instrumentation and electrical design

- Metering

- Temperature Probes

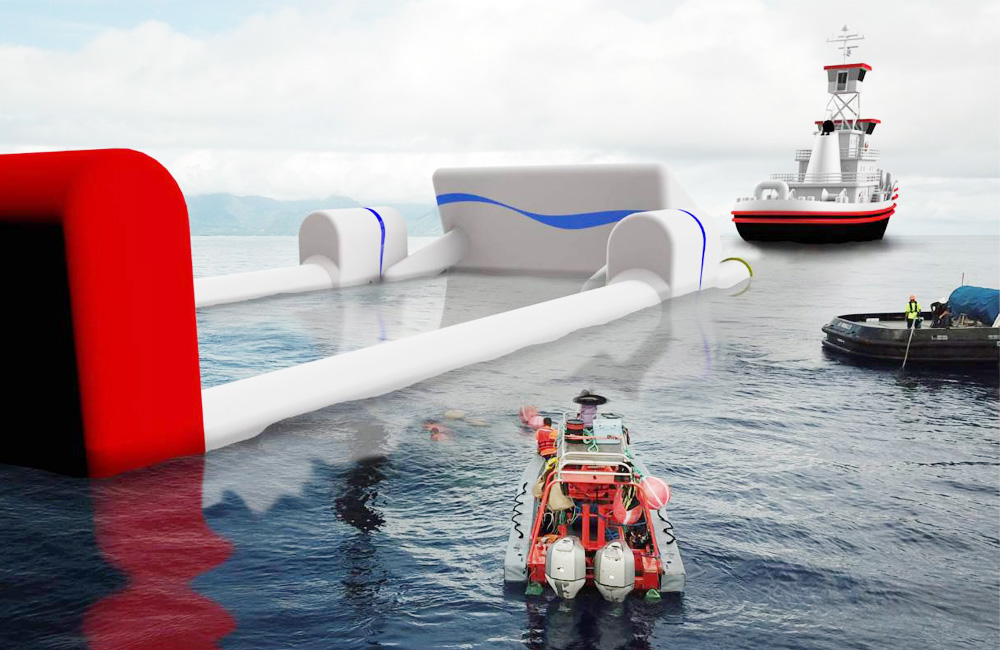

Pressure vessels, tanks, station designs, stainless steel tanks, vessels and piping, storage tank design, Finite Element Analysis (FEA), pipeline system design, rotating machinery, hydraulic system design, and cogeneration design.

Filtration and potable water systems design capability.

Oil and gas processing and petrochemical processing including: offshore and onshore facilities, hydrocarbon loadout, blending, export and receiving facilities; gas compression facilities, gas and liquids metering facilities, crude oil separation and handling, condensate stabilisation, gas dehydration, NGL recovery, LPG fractionation, tankage and storage, gas sweetening and CO2 recovery. Beyond oil and gas the consortium can also deliver processing design for the food and beverage, dairy and wine industries.

Vertical and horizontal separators according to API 12J Specification, DEP 31.22.05.11-Gen and GPSA standard.

Basket strainers and Y-strainers to meet all requirements of gas, oil and diesel systems.

Design and manufacture of small and medium sized decentralised wastewater treatment systems, including permanently submerged and aerated fixed bed systems