Engineering Services

Our capabilities

Engineering Services:

From blast and paint to boiler maintenance, procurement, project management, scaffolding, and specialist bolting technical consulting, we offer a wide range of services to support your projects.

Full blast and paint capacity including offshore and onshore oil & gas maintenance.

Complete overhauls and statutory marine surveys, plus contract maintenance.

Corrosion Control Products including coatings and linings with barrier technology. Corrosion resistant coatings for corrosive chemicals. Also heavy duty coatings and linings using barrier technology for protecting steel and concrete.

Compressor installation and maintenance in AIR and CNG

The Consortium can deliver complete maintenance management, preventative maintenance, predictive maintenance, plant decommissioning and relocation projects, plant maintenance, computerised maintenance management systems, full documentation and training, shutdown planning and management, reliability engineering, asset management, materials management, maintenance execution, specialist troubleshooting, tank maintenance, valve refurbishment and testing, hydro testing, piping repair, hydraulic service repairs, condition monitoring services, metal extrusion industry support.

Comprehensive support is also provided for extrusion press installation, repair, commissioning and retrofitting, and full weld repair services to cylinders in frame for the metal extrusion industry.

Mobile container workshops and portacom office facilities that can be mobilised anywhere in New Zealand and selected locations oversea.

Full multi-disciplined trades capability and all associated site equipment necessary for the timely execution of any plant installation.

Well-established record of accomplishment in the procurement of project materials and equipment using the best international sources of materials and equipment. Also expediting materials and inspection.

Project management of long-term and short-term performance-based contracts. Other roles include turnkey project management, construction planning and cost control, construction management, facilities management, maintenance execution, small project execution and minor modifications, execution of medium to large projects, engineering, shutdown management and execution, technical field support and full final documentation (design, operating and maintenance manuals).

In-house capacity for both on and offshore oil and gas, structural steel, pulp and paper, chemical, building, commercial, mechanical, building and power generation industries.

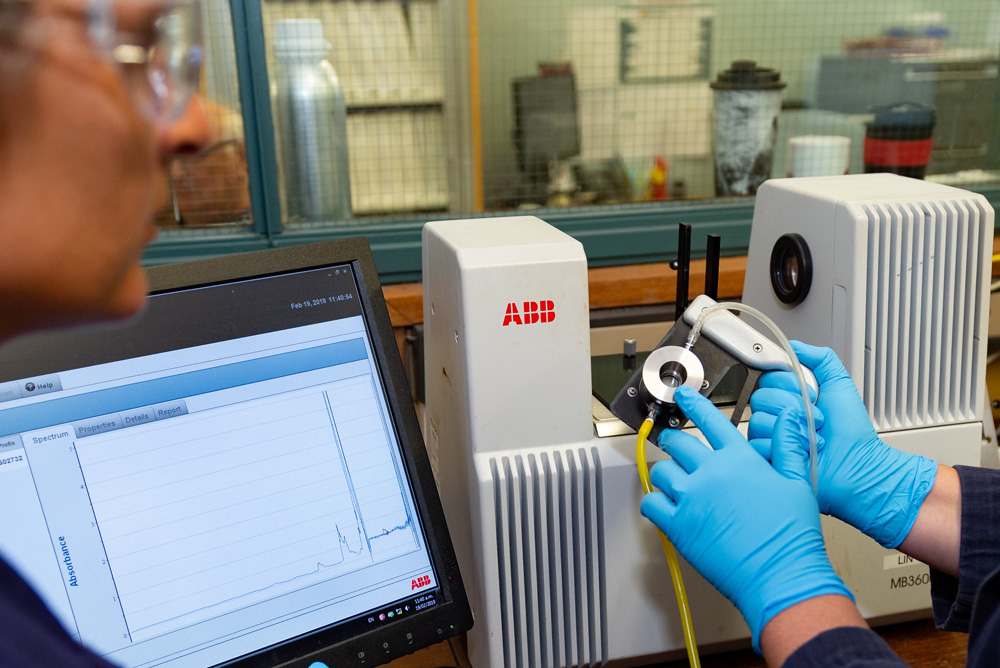

Comprehensive technical consultancy services to identify potential bolting problems, provide solutions and supply specialist equipment to ensure the maximum integrity of all bolted joint applications. Including: tensioning, torqueing, flange breakout, ultrasonic bolt stress monitoring, equipment hire, quality assurance.